Understanding Form Utility

Form utility is a term used in logistics and supply chain management to describe the value that is added to a product or service through manufacturing, processing, or other value-added activities. The term is commonly used to refer to the transformation of raw materials into finished goods, which adds value to the product and makes it more desirable to customers.

Form utility is one of the four types of utility in marketing, alongside time, place, and possession utility. Time utility refers to the value added to a product or service by making it available at the right time, while place utility refers to the value added by making the product or service available in the right location. Possession utility refers to the value added by making it easy for customers to purchase and own the product or service.

How is Form Utility Created?

In logistics, form utility is created through a variety of processes, including manufacturing, assembly, packaging, and labeling. These processes transform raw materials and components into finished goods that meet customer needs and preferences. Form utility is important in logistics because it can affect the price, quality, and availability of products and services, as well as customer satisfaction levels.

Creating form utility requires careful planning and management of logistics operations. This may involve optimizing production processes, managing inventory levels, and coordinating logistics activities across the supply chain. By focusing on creating form utility, logistics managers can add value to products and services, improve customer satisfaction, and enhance overall supply chain performance.

Real-World Examples of Form Utility

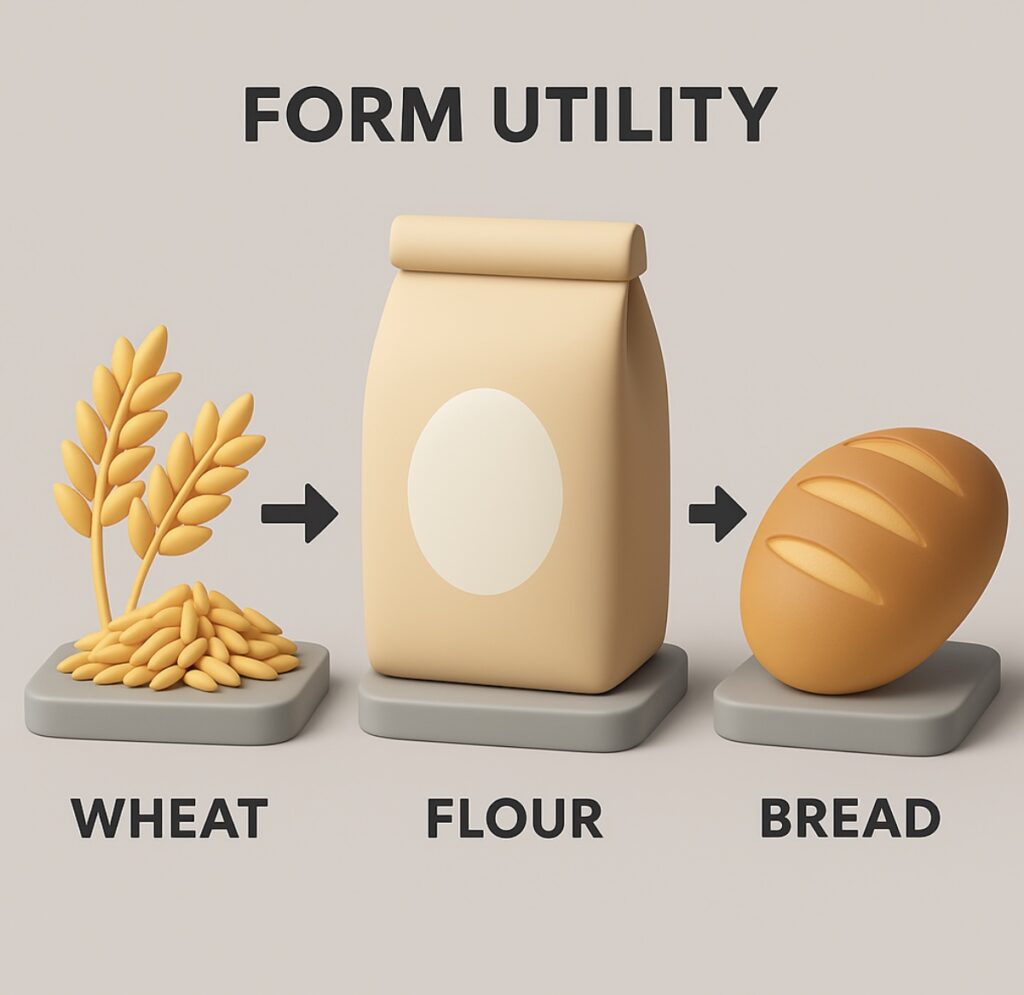

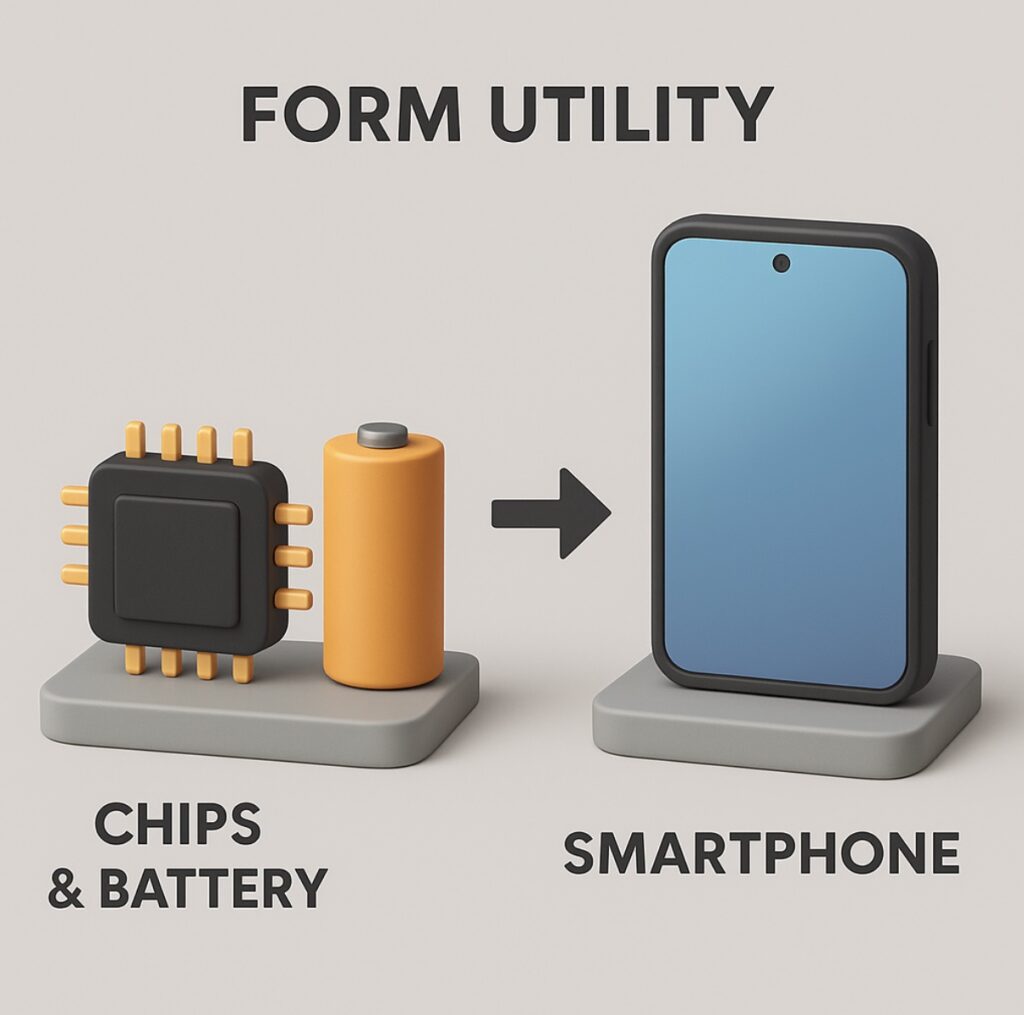

To grasp form utility more concretely, it’s helpful to look at real-world examples:

Food Industry: Raw wheat is processed into flour, which is then used to bake bread. Each step transforms the product, making it more valuable and desirable to the end consumer.

Electronics: Manufacturers assemble individual components like chips, screens, and batteries into a complete smartphone. This assembly creates form utility, turning otherwise useless parts into a high-demand product.

Apparel: Textiles are cut, stitched, and branded into fashionable clothing, adding form utility through design and presentation.

Each of these examples highlights how transformation increases the product’s market value and aligns it with consumer needs.

The Role of Technology in Enhancing Form Utility

Modern logistics operations are increasingly driven by technology. Automated assembly lines, robotics, and AI-powered quality control systems have revolutionized how form utility is created. For instance, robotics not only speeds up the production process but also ensures consistency and precision, which is critical in industries like automotive or electronics manufacturing.

AI and machine learning help identify defects early, optimize workflows, and predict maintenance needs, ensuring the process of creating form utility is smooth and reliable. Technologies like 3D printing are also paving the way for on-demand manufacturing, enabling businesses to create form utility more flexibly and efficiently.

Form Utility vs. Other Utilities: A Deeper Comparison

While form utility is essential, it works best in tandem with the other types of utility:

Time Utility: A well-assembled product must also be delivered when the customer needs it. For example, winter coats have high form utility but only if they reach stores before the cold season.

Place Utility: The perfect product is useless if it’s unavailable where consumers can buy it. Distribution centers and logistics hubs ensure products are positioned close to demand points.

Possession Utility: Even with the right product at the right time and place, if the purchasing process is difficult, utility is lost. Seamless checkout processes, financing options, and digital wallets enhance possession utility.

Understanding how these utilities interact helps businesses craft strategies that maximize overall value creation.

Quality Control and Its Impact on Form Utility

Quality control is a cornerstone of form utility. A well-made product enhances brand reputation, fosters customer loyalty, and reduces return rates. Rigorous testing and inspections ensure that each product meets specifications and safety standards.

For example, in pharmaceuticals, strict quality control during manufacturing ensures that medicines are safe and effective, adding significant form utility. Similarly, in the automotive industry, testing each vehicle part ensures the final assembly operates reliably.

Sustainability and Form Utility

In today’s market, sustainability is a growing factor in perceived value. Companies that prioritize eco-friendly materials, minimize waste, and use renewable energy in production processes add a new layer of form utility.

For instance, brands that offer biodegradable packaging or recycled materials tap into consumer demand for sustainability, making their products more attractive and competitive.

Sustainability also extends to circular logistics. By designing products that can be easily recycled, refurbished, or repurposed, businesses can retain form utility even after initial use, contributing to the circular economy.

Challenges in Creating Form Utility

Creating form utility isn’t without challenges:

Supply Chain Disruptions: Delays in raw material procurement can halt production lines, affecting the timely creation of form utility.

Labor Shortages: Skilled labor is often necessary for specialized manufacturing, and shortages can bottleneck operations.

Regulatory Hurdles: Compliance with safety and quality regulations requires continuous updates to processes and documentation.

Cost Pressures: Balancing cost-efficiency with high-quality production is a delicate task, especially in competitive industries.

Navigating these challenges requires robust planning, risk management, and flexible logistics strategies.

Customization and Form Utility

Mass customization—offering products tailored to individual preferences—has transformed how form utility is perceived. Whether it’s personalized sneakers, custom-built furniture, or made-to-order electronics, customization enhances form utility by meeting unique customer desires.

This trend has pushed logistics companies to adapt, incorporating flexible manufacturing systems and agile supply chains that can handle a variety of product variations without sacrificing speed or quality.

The Economics of Form Utility

Form utility directly impacts pricing strategies and profitability. Products that undergo extensive transformation typically command higher prices, reflecting the added value. However, businesses must also consider production costs and market demand to maintain profitability.

For example, a handcrafted leather bag may have high form utility and a premium price point, but if production costs outweigh demand, profitability suffers. Balancing value creation with cost management is essential for economic success.

Form Utility in Reverse Logistics

Reverse logistics—handling product returns, recycling, and refurbishing—also plays a role in form utility. Returned items can regain their value through repair, repackaging, or recycling, reducing waste and recovering lost revenue.

For instance, tech companies often refurbish returned electronics, restoring form utility and reselling them at a discount, which appeals to cost-conscious consumers and supports sustainability goals.

Future Trends in Form Utility

Looking ahead, several trends are set to shape form utility:

Industry 4.0: Smart factories will integrate IoT, AI, and robotics for hyper-efficient, self-optimizing production lines.

3D Printing: On-demand manufacturing will enable localized production and rapid prototyping, enhancing flexibility.

Sustainable Materials: Demand for eco-friendly inputs will continue to grow, pushing companies to innovate in material science.

Blockchain: Enhanced traceability and transparency in supply chains will ensure product authenticity and compliance, reinforcing form utility.

These trends promise to make form utility creation more dynamic, efficient, and aligned with evolving consumer and regulatory expectations.

How Waredock Enhances Form Utility in Logistics

At Waredock, we understand that form utility is fundamental to customer satisfaction and business success. Our state-of-the-art facilities and experienced team ensure that every product is processed, packaged, and prepared with precision and care. Whether it’s assembly, labeling, or specialized packaging, we tailor our services to meet your unique requirements.

By leveraging advanced technology, sustainable practices, and robust quality control systems, Waredock helps businesses maximize the value of their products at every stage of the supply chain. We seamlessly integrate form utility with time, place, and possession utilities to deliver a complete logistics solution that drives results.

Ready to elevate your logistics strategy? Contact Waredock today to discover how we can help you add value, streamline operations, and exceed customer expectations.